The main causes of SFP optical module failures

SFP optical module failures typically occur at both the sending and receiving ends. The most common problems mainly focus on the following aspects:

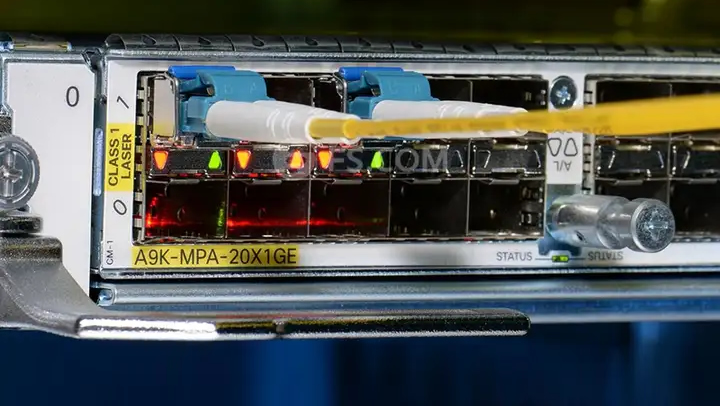

Optical port contamination and damage

There are several reasons that can cause SFP optical port failures. For example, prolonged exposure of SFP ports to the environment and contamination by dust, or the use of contaminated fiber optic end faces to connect SFP optical modules, may lead to secondary contamination. In addition, connecting scratched or poor quality fiber optic cables to 1G SFP optical modules can also cause SFP optical module failures. The failure of these SFP optical modules will result in transmission interruption, making your 1-gigabit link unable to function properly.

ESD damage

The optical module is damaged due to ESD (electrostatic discharge). Electrostatic discharge can adsorb dust, alter the impedance between circuits, and affect the functionality and lifespan of 1000Base SFP optical modules. There are two factors contributing to ESD damage. One is to generate electrostatic discharge in a dry environment. Another issue is that the 1000Base optical module is not packaged with anti-static packaging, or the static sensitive pins are not protected by static electricity, resulting in the SFP optical module not working properly.

Compatibility issues

In addition to the above reasons, compatibility issues with SFP optical modules cannot be ignored. If a technician inserts an SFP module into an SFP+port, or installs a 1310nm SFP optical module on the A end and an 850nm optical module on the B end, it will cause compatibility issues. Furthermore, although most suppliers guarantee full compatibility of their SFP optical modules, this may not be the case in reality. Technicians must ensure that the SFP optical module is compatible with their equipment before purchasing.

Tips for troubleshooting SFP optical modules

Optical interface protection

To protect the SFP optical module ports from dust damage, the correct practice is to use dust plugs on unused 1000Base SFP optical modules. Before connecting the fiber optic cable, it is best to use a cleaning pen to clean the interface between the fiber optic and SFP optical module.

Handle the light emitting module gently to avoid falling.

When installing the optical module, gently push it in by hand. When disassembling the optical module, first loosen the fixing clip. Do not use any metal tools during installation and disassembly.

Use a dedicated cotton swab to clean the light holes of the light module, and do not insert any metal objects.

ESD protection

Here are some tips to avoid ESD, applicable to 1GB SFP optical modules.

When transporting optical modules, make sure they are in ESD packaging and do not remove or place them randomly.

Before touching the light module, wear an ESD static wristband or ESD gloves. Take comprehensive ESD measures when installing optical modules.

Ensure that the equipment is properly grounded before testing or use.

When plugging and unplugging non hot swappable optical modules, the power should be cut off.

Compatibility troubleshooting

Following these tips can help avoid some compatibility issues.

Check that the SFP or SFP+optical module is inserted into the correct port. SFP and SFP+modules have the same packaging, and SFP optical modules can be seamlessly inserted into SFP+switch ports, and vice versa. However, please note that installing SFP+modules on SFP ports will not automatically run as 10G optical modules may not be able to automatically negotiate to 1Gbps.

Ensure that the wavelengths at both ends of the SFP optical module are the same. Additionally, please check if the SFP optical module matches the correct fiber optic. For example, a 1310nm single-mode SFP optical module must be used in conjunction with a single-mode fiber, while an 850nm multi-mode SFP optical module requires the use of a multi-mode fiber for connection. Mixed use will result in signal loss and failure of other SFP optical modules.

Ensure that the SFP Ethernet optical module matches your device. Some brands only allow the use of their own modules. Because all optical modules actually have a burning chip containing serial number, safety information, and supplier ID information. If the information does not match the information in the database, the device will not function properly.

How to determine if the SFP optical module is working properly?

Test whether the optical power is within the required range. If there is no light or the light power is low, the wavelength and measurement unit (dBm) should be checked. Clean and inspect the end face of the fiber optic connector and the optical port of the optical module, check for any black, scratches, or bends on the end face of the fiber optic connector, and then replace the fiber optic connector or optical module for interoperability testing.

The optical power is normal, but the link cannot be established. Check the connection light. This issue involves wiring. The use of poor quality or incorrect cables, incorrect wiring, or cables with loops may cause this problem.

After inserting the SFP optical module, the port enters an error disabled state (software damage). Remove the SFP optical module from the port and replace it with an authorized module. If you still cannot recognize the SFP optical module, please check if the module is inserted upside down, check the module ports, or replace the authorized module for interoperability testing.