Products Description

DC to 10 Mbd Versatile Link Fiber Optic Analog Transmitter for 1 mm POF and 200 µm PCS

Description

The AFBR-1529Z analog transmitter utilizes a 650 nm LED source in a housing designed to efficiently couple into 1 mm Polymer Optical Fiber (POF) and 200 µm diameter Plastic-Clad Silica (PCS). Links up to 50 m are supported with 1 mm POF, and up to 200 m with 200 µm PCS. It is designed to interoperate with Avago´s HFBR-25xxZ, AFBR-25xxZ and AFBR-26xxZ receivers. The transmitter is a 4-pin device, packed in Versatile Link housing. Versatile Link components can be interlocked (N-plexed together) to minimize space and to provide dual connections with the duplex connectors. Various simplex and duplex connectors, as well as POF cables are available for Versatile Link components. Please contact Avago Technologies for details or visit our company website at www.gigac.com

Features

RoHS-compliant

Data transmission at signal rates from DC up to 10 MBd

Up to 50 meters distance with 1 mm Plastic Optical Fiber (POF) and 200 meters with 200 µm PCS

Operating temperature range of -40 °C to +85 °C

Compatible with Avago’s Versatile Link family of connectors, for easy termination of fiber

Applications

Industrial control and factory automation

Serial field buses

Intra-system links; Board-to-Board, Rack-to-Rack

Extension of RS-232 and RS-485

High voltage isolation

Elimination of ground loops

Reduces voltage transient susceptibility

Package and Handling Information

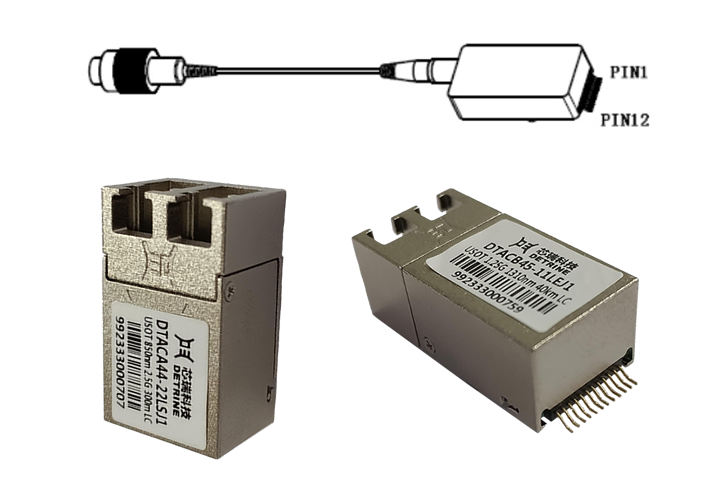

The Versatile Link package is made of a flame retardant VALOX1 UL 94 V-0 material and uses the same pad layout as a standard, eight pin dual-in-line package. These Versatile Link packages are stackable and are enclosed to provide a dust resistant seal. Snap action simplex, simplex latching, duplex, and duplex latching connectors are offered with simplex or duplex cables.

Package Housing Color

Versatile Link components and simplex connectors are color coded to eliminate confusion when making connections. Receivers are black and transmitters are grey.

Handling

Versatile Link components are auto-insertable. When wave soldering is performed with Versatile Link components, the optical port plug should be left in to prevent contamination of the port. Do not use reflow solder processes (i.e., infrared reflow or vapor-phase reflow). Non-halogenated water soluble fluxes (i.e., 0% chloride), not rosin based fluxes, are recommended for use with Versatile Link components.

Versatile Link components are moisture sensitive devices and are shipped in a moisture sealed bag. If the components are exposed to air for an extended period of time, they may require a baking step before the soldering process. Refer to the special labeling on the shipping tube for details.

Interlocked (Stacked) Assemblies (refer to Figure 4)

Horizontal packages may be stacked by placing units with pins facing upward. Initially engage the inter-locking mechanism by sliding the L bracket body from above into the L slot body of the lower package. Use a straight edge, such as a ruler, to bring all stacked units into uniform alignment. This technique prevents potential harm that could occur to fingers and hands of assemblers from the package pins. Stacked horizontal packages can be disengaged if necessary. Repeated stacking and unstacking causes no damage to individual units.

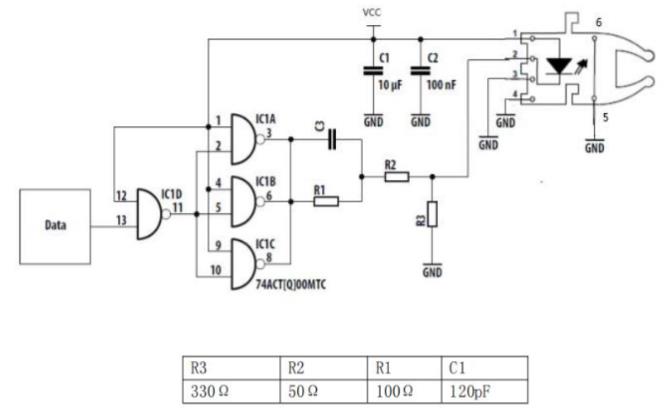

Recommended Launch Application Circuit

Our factory

The Evolution and ···

Wavelength Divisio···

Detailed Explanati···

The Working Princi···

Hot Tags:

R&D laboratory

Gigac has introduced numerous precision testing equipment, such as Ixia XGS12, Ixia WaveTest 93, Anritsu, Fujikura, Fluke, JDSU, Agilent, EXFO, DATA-PIXEL, etc., for product development testing and validation.At present, there are over 100 professional engineers, of which 50% are senior engineers. Through standardized testing processes and in line with international professional testing standards, we provide testing in various aspects such as product appearance, performance, compatibility, and solution scenarios to meet the diverse testing needs of global customers.

Numerous research and development achievements

Gigac adopts a research and development model that combines independent research and joint development, and has achieved outstanding results in industrial design and product software and hardware research and development.As data centers continue to expand and grow, a well planned cabling infrastructure is crucial. Without flexible cabling plans that can easily adapt to common moves, additions, and changes, your network growth will be limited. The Gigac series high-density data center cabling solutions can simplify deployment, enabling up to 144 LC fibers in 1U, and enabling flexible expansion and rapid upgrades with increasing business traffic demands.

Gigac Test Center

Gain a comprehensive understanding of Gigac's optical modules, fiber optic jumpers, and enterprise network testing center. We have a comprehensive testing plan, professional testing equipment, and standard testing procedures. We regularly test optical modules, cables, switches, and other products to ensure that we provide high-quality products to our partners.