Products Description

Product Features

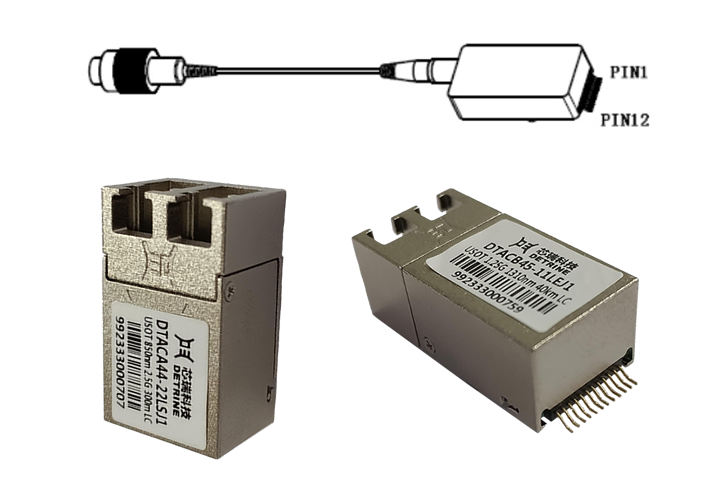

Comply with the GJB599B (MIL-DTL-38999M) III series standard

Triple-start thread for quick connection with anti-loosening structure

Five-key circumferential identification and positioning for blind mating and error-proof insertion

Outer shell available in different materials and coatings to adapt to various environmental requirements

Equipped with electromagnetic shielding function

Compact size, lightweight, and high contact density

Suitable for use in complex environments with strong vibrations, rain, windblown sand, and humidity

Capable of mixed mounting of power, high-speed, high-frequency, and optical contacts

Integrated connection of microwave signals, high-speed data, optical fibers, and power control signals

Mechanical Performance

• Mechanical Life:

500 cycles of insertion and extraction

• Shock:

3ms half-sine wave with a peak acceleration of 300G

• Vibration:

Sine: 60G with temperature cycling and simulated conditions (36 hours)

Random: 44.1grms at high temperature

49.5grms at ambient temperature

Environmental Performance

• Temperature Range:

Class K, F: -65°C to +200°C

Class W, MW: -65°C to +175°C

• Sealing:

Mating connectors comply with the low-pressure immersion requirements of MIL-DTL-38999M

• Salt Spray:

Class K: 500 hours

Class F: 48 hours

Class W: 500 hours

Class MW: 192 hours (acidic atmosphere)

• Damp Heat:

As per MIL-DTL-38999M: 24 hours, 10 cycles

• Fluid Resistance:

Resistant to various fuels, coolants, and solvents

Electrical Performance

• Voltage Endurance: V

Operating Conditions | Sea Level | 21,000M Altitude |

M | 1300 | 800 |

N | 1000 | 600 |

I | 1800 | 1000 |

II | 2300 | 1000 |

• Insulation Resistance: ≥5000MΩ (at 500V DC)

• Contact Resistance and Rated Current of Contacts:

Contact Specifications | Working Diameter (mm) | Contact Resistance (mΩ) | Rated Current (A) |

22D | Φ0.76 | ≤12 | 5 |

20# | Φ1.00 | ≤5 | 7.5 |

16# | Φ1.60 | ≤2.5 | 13 |

12# | Φ2.40 | ≤1.5 | 23 |

10# | Φ3.15 | ≤1.0 | 40 |

Shielded Contacts

Low-Level Contact Resistance (Applicable to Inner Contacts Only):

Contact Specifications | Initial Value(mΩ) | After Testing(mΩ) |

16# | 170 | 204 |

12# | 55 | 66 |

Contact Resistance (Test Current and Voltage Drop):

Contact Specifications | Contact | Test Current (A) | Voltage Drop max (mV) | |||

25℃ | 175℃ | 200℃ | ||||

Normal Conditions | After Testing | |||||

16# | Inner Contact | 1 | 170 | 204 | 290 | -- |

Outer Contact | 12 | 150 | 180 | 255 | -- | |

12# | Inner Contact | 1 | 170 | 204 | -- | 290 |

Outer Contact | 12 | 150 | 180 | -- | 255 | |

Withstand Voltage (Between Inner and Outer Contacts):

750V RMS (Root Mean Square) at Sea Level

250V RMS at 15,240 meters (approximately 50,000 feet)

12# Coaxial Contact

Nominal Impedance: 50 Ω

Low-Level Contact Resistance (Applicable to Inner Contacts Only):

Initial Value: 55mΩ

After Testing: 66mΩ

Withstand Voltage (Between Inner and Outer Contacts):

1000V RMS at Sea Level

250V RMS at 15,240 meters

Contact Resistance (Test Current and Voltage Drop):

(Specific values, test current, and voltage drop levels need to be determined according to the product design or relevant standards.)

Voltage Standing Wave Ratio (VSWR):

Within the frequency range of 500MHz to 3GHz, the VSWR should not exceed 1.2 + 0.04F, where F is the frequency in GHz, under the following three conditions:

(This specification ensures that signal reflections remain within acceptable limits during transmission through the coaxial contact, thereby maintaining signal transmission efficiency and quality.)

Our factory

The Evolution and ···

Wavelength Divisio···

Detailed Explanati···

The Working Princi···

Hot Tags:

R&D laboratory

Gigac has introduced numerous precision testing equipment, such as Ixia XGS12, Ixia WaveTest 93, Anritsu, Fujikura, Fluke, JDSU, Agilent, EXFO, DATA-PIXEL, etc., for product development testing and validation.At present, there are over 100 professional engineers, of which 50% are senior engineers. Through standardized testing processes and in line with international professional testing standards, we provide testing in various aspects such as product appearance, performance, compatibility, and solution scenarios to meet the diverse testing needs of global customers.

Numerous research and development achievements

Gigac adopts a research and development model that combines independent research and joint development, and has achieved outstanding results in industrial design and product software and hardware research and development.As data centers continue to expand and grow, a well planned cabling infrastructure is crucial. Without flexible cabling plans that can easily adapt to common moves, additions, and changes, your network growth will be limited. The Gigac series high-density data center cabling solutions can simplify deployment, enabling up to 144 LC fibers in 1U, and enabling flexible expansion and rapid upgrades with increasing business traffic demands.

Gigac Test Center

Gain a comprehensive understanding of Gigac's optical modules, fiber optic jumpers, and enterprise network testing center. We have a comprehensive testing plan, professional testing equipment, and standard testing procedures. We regularly test optical modules, cables, switches, and other products to ensure that we provide high-quality products to our partners.